Technical news

Stay ahead of the competition with the latest technical news and updates.

Find out more1 February 2023

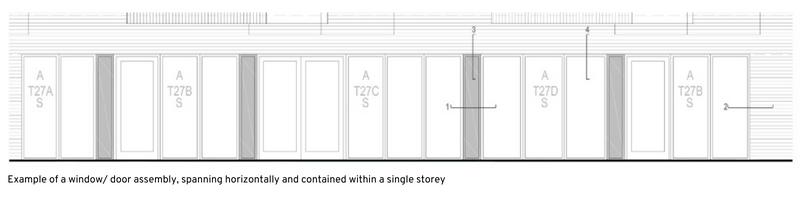

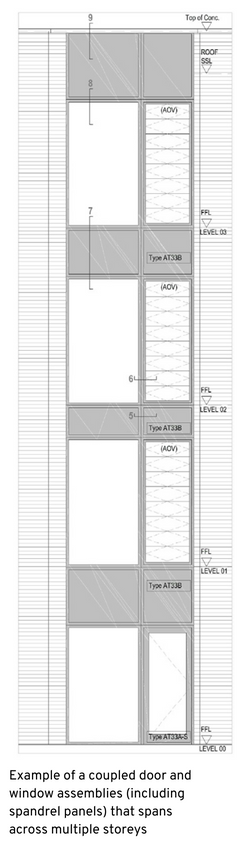

A question frequently asked of our technical staff relates to facades being formed with a series of window units coupled vertically with intermediate spandrel panels and sometimes with doors included where the assembly is connected horizontally across each storey. Also, it is normal for spandrel cladding panels to be installed where the assembled façade spans across the construction at each floor level.

A window wall is an assembly of individual units that must have substantial support from the surrounding building structure. When the window wall spans across several floor levels this composite installation also requires specially designed flitch plates at connections within the assembly to provide structural continuity between elements. Therefore, most window walls are based on a bespoke design approach without preliminary offsite testing. But it is necessary for these designs to prove their performance in delivering resistance to wind pressure and water penetration together with meeting the requirements for airtightness.

Curtain walling systems are normally based on a fully engineered framework of mullions and transoms that are designed and manufactured to support glazing elements, spandrel panels and ancillary attachments such as solar shading or door units to be incorporated within the system. For NHBC Warranty acceptance Curtain Wall Systems are required to have been Type Tested and to comply fully with BS EN 13830: 2015 Curtain Walling - Product Standard.

We have had serious concerns about some window wall arrangements where they have not been correctly designed and have no track record or proof of performance from offsite testing. This always raises question of how any ad-hoc assembly of windows, doors and panels can reliably provide the necessary assured service-life and design performance in accordance with relevant standards. These multiple combinations of windows/panels/doorsets are often bespoke and lacking in any previous history of reliable of performance. So, they cannot reliably demonstrate the compliances for systemised design and proof of performance as required in NHBC Standards Chapter 6.7 ‘Doors, Windows and Glazing’ and Chapter 6.9 ‘Curtain Walling and Cladding’.

Previously it was necessary to update the original NHBC Standards Chapter 6.7 by improving on some of the key information that aids in the management of technical risk. This was particularly relevant in relation to assemblies including windows, panels and doors that had become increasingly common on façade installations for small to medium rise multi-storey residential building schemes.

To revise Chapter 6.7 NHBC set up a Task Group including industry experts with the task of identifying what changes should be made to our Standards and how they could be implemented to best effect. This working committee included representatives from manufacturers, certification bodies, external standard setting organisations and NHBC.

The Task Group agreed on the following:

The revised NHBC Standards Chapter 6.7 was initially published in the 2013 edition of NHBC Standards which had its first distribution in Autumn 2012. The 2021 edition has been further updated to provide guidance on the design principles of coupling joints between doors, windows, and spandrels, and clarify the off-site testing requirements for assemblies which are contained within a single storey or structural floor and ceiling. It has since been found that the technical risk issues can be significantly reduced when builders and their specialist contractors, including designers, follow the principles set out in Chapter 6.7 including points 1 to 3 above in compliance with the relevant Chapters in our Standards.

Curved curtain walling systems are not normally tested off-site due to the limitations of test rigs and equipment but the performance requirements for air, wind and water resistance are the same as plain curtain walling systems. Site water testing in accordance with performance standard 6.9.17 is required to confirm that curved curtain walling is installed in accordance with the design and in-service performance is met. Site water testing of curved curtain walling should include both system joints and interfaces which are intended to be permanently closed and watertight.

Single doorsets and individual window units – would normally be defined as an individual opening within a wall or roof, with glazing sealed into a support frame. NHBC Standards Chapter 6.7 ‘Doors, windows and glazing’ provides guidance on design, specification for performance and installation of windows and doors.

Window and door frame assemblies – windows, doors and spandrel panels connected, spanning vertically/ horizontally, and connected to the supporting structure. Assemblies should be designed as an engineered system to support its self-wight and imposed loads safely to the supporting structure.

Coupling joints between doors and window frames (including spandrel panels) should be designed with a dual sealed approach to joints comprising outer seals as the primary water barrier, inner seals providing air and secondary water barriers and a drained cavity to remove any water that by passes the outer seal.

Assemblies should be formed as a system using products and materials fully specified by the manufacturer for required service life performance and durability. NHBC Standards Chapter 6.7 ‘Doors, windows and glazing’ provides guidance on design, specification for performance and installation of assemblies contained within a single storey and chapter 6.9

Curtain Walling provides relevant guidance for assemblies spanning across multiple storeys. Curtain wall systems – provide the exterior building envelope and should be designed to support their own weight and the loads imposed on them e.g., wind loads and be fully supported by properly designed connections to primary elements of the building structure. Curtain wall systems must also be designed to form a weather resistant external building envelope and as such they need to perform in all respects to resist wind effects, give required airtightness and maintain fully effective resistance to water ingress.

The information given in NHBC Standards Chapter 6.9 Curtain Walling contains guidance for curtain walling design, specification, performance, and installation. Variations of curtain walling systems - are all conventionally defined as non-load bearing systems with framed supports comprising vertical and horizontal members (mullions and transoms) structurally connected as a fully designed system.

Coupled door and window frames (including spandrel panels) that span one or more storeys will need to be assessed and certificated to ensure suitable design, satisfactory in-service performance, and appropriate long-term durability, all in accordance with Chapter 6.9. To ensure satisfactory weatherproofing the assessment should include testing of the proposed joint details at interfaces with the building and the coupling joint between door and window frames.

Testing should be carried out in accordance with recognised Standards. Additional items to be considered in the assessment include loads, movement, brackets and fixings, air infiltration, condensation, acoustic performance, tolerances, and durability. The certification and proofs of performance should be made available to NHBC in advance of the system being installed on site.

With reference to compliance in accordance with Standards Chapter 6.9 performance standard 6.9.7- site water testing should be carried out to confirm the quality of installation relating to waterproofing for weather resistance. This should be site hose testing carried out by a UKAS accredited test organisation and include a fully representative number of façade joints and interfaces that have been designed to be permanently waterproof. NHBC may request an opportunity to see the testing if required as part of our site quality and risk management process and we will always want to receive the test results in a written report from the UKAS testing company as soon as possible after completion.

Stay ahead of the competition with the latest technical news and updates.

Find out moreNHBC is uniquely placed to offer relevant, best practice technical training.

View coursesYour essential guide to house building from foundations to roofs and finishing.

Read moreTechnical queries and quotes

Any technical information contained on this website is produced by NHBC as guidance solely for all our builder customers as to how to interpret the technical requirements in relation to the warranty cover provided by NHBC under its Buildmark, Buildmark Choice, Buildmark Link, Buildmark Solo, Buildmark Connect or any similar product from time to time. It has not been created or intended for distribution or use outside of that purpose. The technical information contained on this web page does not constitute advice and is not to be relied upon by any third party. Nothing on this web page is intended to, nor should it be taken to, create any legal or contractual relationship. Any third party who chooses to rely upon the information contained on this web page shall do so entirely at their own risk and NHBC accepts no duty of care or liability, however caused, in connection with its use or reliance by any third party.